PharmTech: Could you explore the most important discrepancies that must be regarded as when formulating a small molecule or a biologic as a parenteral drug?

In horizontal flow purposes, it involves the usage of air returns with the downstream boundary of the procedure. The usage of ceiling mounted air returns is contradictory to right cleanroom process layout.

In case you’re seeking to steer clear of freight reclasses, the one way to be sure your class is to confirm your freight class employing the correct NMFC code, and making certain it is actually noticeable and legible about the freight BOL made use of at some time of pickup. Your LTL shipping and delivery pro will let you do that, as they should have entry to the NMFC database. Beneath, we’ve also incorporated a number of classing suggestions to keep the delivery easy and straightforward:

Ebola virus an infection is daily life threatening Pretty much ninety five% of infected men and women lost their existence. Only in several instance in United states hospitals like Nebrask...

These techniques are meticulously picked to offer an extensive image from the cleanliness stage in the sterile production environment. The crucial element sampling techniques involve:

This step is important to stop contaminants from coming into the cleanroom and compromising the sterility of your producing natural environment.

Grade C cleanrooms are utilized for fewer critical levels within the production system. They obtain programs in the following activities:

The higher the density, the lessen the class and eventually, the reduce class 100 area the cost. This might seem backward in the beginning look, but think about this: carriers really like shipping and here delivery freight which is large and doesn’t take up much Room when compared with its pounds.

Designing a GMP-compliant cleanroom necessitates mindful thought of various variables. Here are several vital design and style criteria to make sure GMP compliance:

Planning of elements and most merchandise (some solutions with significant or abnormal pitfalls of microbial contamination could have to have Grade C)

Cleanroom classification restrictions are normally standardized based on market criteria and polices. Having said that, in some instances, restrictions can be modified dependant on an intensive threat assessment and scientific justification, taking into consideration the particular wants with the production procedures.

[thirteen] UV gentle has Beforehand been utilized to wash surface area contaminants in sterile environments such as hospital functioning rooms. Their use in other cleanrooms could raise as tools results in being a lot more inexpensive. Prospective advantages of UV-based mostly decontamination features a lowered reliance on chemical disinfectants as well as the extension of HVAC filter existence.

The “clean up up” period is time taken to revive the cleanroom to its qualified condition soon after manufacturing functions. It is essential for retaining steady cleanliness levels and blocking the persistence of contaminants launched in the course of functions.

PharmTech: About the next decade, what tendencies would you anticipate will affect the parenteral drug formulation space?

Devin Ratray Then & Now!

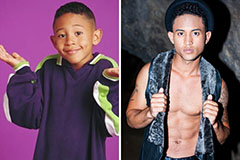

Devin Ratray Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Batista Then & Now!

Batista Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now!